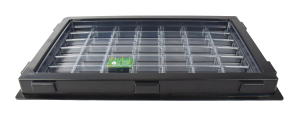

Are you seeking the perfect static shield for your sensitive electronics, while also eradicating the risk of Foreign Object Debris (FOD) contamination? Look no further! ESD-Safe Thermoformed Plastic offers an unparalleled combination of advanced protection and reduced FOD, making it the ultimate choice for safeguarding your products and revolutionizing your operations.

Advantages of ESD-Safe Thermoformed Plastic, Including Reduced FOD:

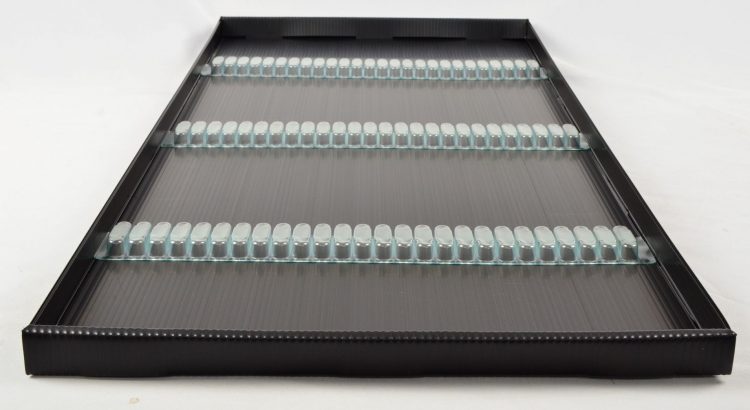

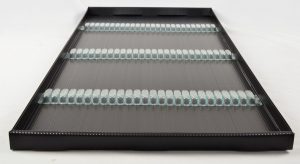

- ESD Protection Like Never Before: Electrostatic Discharge (ESD) can spell disaster for sensitive electronics, leading to costly failures and dissatisfied customers. ESD-Safe Thermoformed Plastic is your secret weapon against such calamities. This ingenious packaging material incorporates conductive and dissipative properties, diverting harmful static charges away from your valuable components, and ensuring optimal product performance and reliability.

- Minimize FOD Risk: Foreign Object Debris (FOD) contamination is a persistent enemy of precision engineering and production processes. ESD-Safe Thermoformed Plastic is engineered to mitigate FOD risks effectively. With custom-fit packaging that securely holds your products in place, the chances of loose particles or debris finding their way into your sensitive electronics are dramatically reduced, safeguarding your reputation for quality and minimizing costly rework.

- Robust and Resilient: ESD-Safe Thermoformed Plastic is not just about static protection; it’s built to withstand the rigors of demanding industries. The thermoforming process results in strong and impact-resistant packaging, ensuring your products arrive safely and in pristine condition. Count on this reliable solution to shield your electronics during transportation, storage, and handling, irrespective of the challenges they may face.

- Streamlined Production and Cost Efficiency: By incorporating ESD protection directly into the packaging, you eliminate the need for additional anti-static materials or treatments. This streamlines your production process, saving valuable time and resources. The cost efficiency and increased throughput translate to a competitive edge in your industry.

- Environmental Responsibility: In the pursuit of sustainability, ESD-Safe Thermoformed Plastic rises to the occasion. Many thermoforming materials are recyclable, contributing to waste reduction and a cleaner planet. Choosing an eco-friendly packaging solution aligns your business with responsible practices, appealing to environmentally-conscious customers and stakeholders.

- Regulatory Compliance Confidence: Industries dealing with sensitive electronics often operate under strict regulations and standards. By adopting ESD-Safe Thermoformed Plastic, you can rest assured that your packaging complies with industry-specific requirements, facilitating smooth audits and maintaining your reputation as a trusted supplier.

Partner with Excellence – Embrace ESD-Safe Thermoformed Plastic!

Incorporating ESD-Safe Thermoformed Plastic into your packaging strategy grants you an unparalleled edge. Protect your electronics from harmful ESD, reduce the risk of FOD contamination, and reap the benefits of streamlined operations and cost savings. Our team of experts is ready to collaborate with you, tailoring ESD-safe packaging solutions that fit your unique needs and specifications.

Don’t let your products fall victim to ESD or FOD; fortify them with ESD-Safe Thermoformed Plastic today! Elevate your protection, empower your business, and let your reputation for excellence soar. Reach out to us now to discover the limitless potential of ESD-Safe Thermoformed Plastic and propel your success to new heights!