This unique system was created to streamline the kitting process to make it more efficient, reduce time, reduce inventory and be universal to each department. The racks were supplied by the customer and CCI created the custom kitting filing system and drawers. Three different sizes were created to accommodate different component and hardware sku’s.

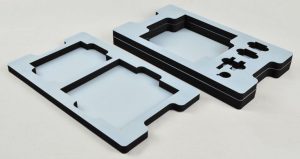

The totes were constructed in CCI’s DT style, made out of conductive fluted plastic, aluminum side rails and corner stackers. Each tote was fitted with a drawer side rail to fit onto the racking. A handle on the front of the tote made for easy access to slide each tote out. A line bent snap on cover was added to keep FOD out and complete the Faraday cage.

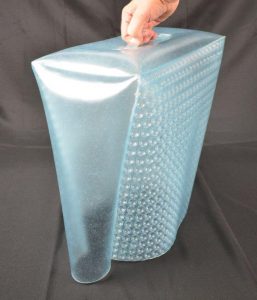

The folders are made out of KleanStat Flex which is an inherently dissipative, IPA cleanable flexible plastic. The sides of each folder are welded so the hardware inside cannot fall out. Each folder has a tab and is numbered for inventory reference. The largest folders are 12 inches wide by 10 inches deep with 30 per tote. The medium tote holds 30 folders that are 12 inches wide by 5 inches deep and the smallest tote has 80 folders that are 5.875 inches wide by 2 inches deep in a two rows of 40 configuration.

By utilizing the number system it makes for quick kitting. A pick list based on associated numbers is used to pull all the necessary components to complete a build. This system decreased the footprint from the previous methods, increased efficiency and made inventory more accurate and accountable.